Related Technical Articles

Fig 1 Life Cycle Assessment (LCA)

Benefits of LCA

- LCA helps to select and compare the products or processes with least environmental impact. This information is useful when combined with other factors like cost and performance to select the right product or process

- LCA allows to study an entire product system. Thus, chances of sub-optimization are significantly reduced

- LCA determines the effects on one or more environmentally sensitive locations.

- LCA helps to discover significant product enhancements and novel approaches to process optimization. In some cases, it results in developing a new product or service to cater to the same need.

Phases of LCA

- Goal and Scope Definition,

- Inventory Analysis,

- Impact Assessment,

- Interpretation

Fig 2: Phases of LCA (1)

- Goal and Scope: The goal of the study is to evaluate the environmental impacts associated with a conventional LLDPE film, and a Biodegradable LLDPE film. In the LCA study, GaBi software is used to model the life cycle of Biodegradable LLDPE film, to make the inventory and to estimate the related environmental burdens following ISO 1440 and 1444 standards.

- Inventory Analysis: It is the identification, collection and calculation of inputs and outputs of environmental flows across the system boundaries. The raw materials, in process intermediates, the finished materials, electricity and water consumption are thoroughly studied, recorded and demonstrated for additive, masterbatch as well as film manufactured using the Biodegradable Additive. The findings are subjected to Impact Assessment using the Gabi Software.

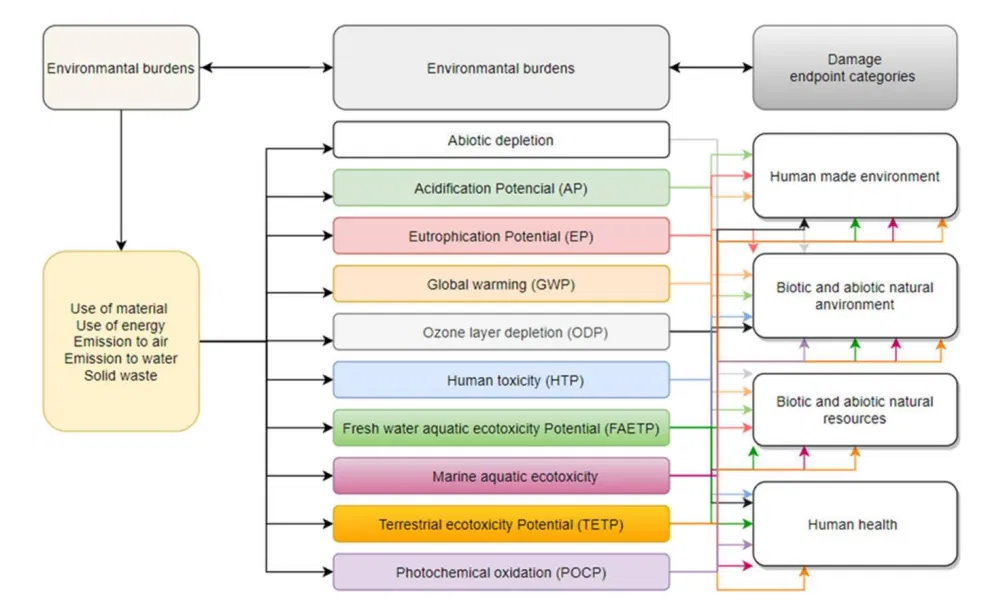

- Impact Assessment: The impact assessment phase of an LCA assigns the results of the inventory analysis to different impact categories(1) . The impact categories considered in the study are shown in Fig 3, and some of the selected categories are included in the study, namely:

- Global Warming Potential (GWP or Carbon Footprint)

- Abiotic resource depletion

- Acidification

- Eutrophication

- Ozone layer depletion

- Photochemical oxidation

- Human toxicity

Fig 3: Impact Categories in LCA (1)

- Global warming (GWP): Global warming potential (GWP) is a measure of how much of a given mass of a greenhouse gas (for example, CO2, methane, nitrous oxide) is estimated to potentially contribute to global warming. It is measured in terms of CO2

- Abiotic depletion: It refers to the depletion of non-living (abiotic) resources such as fossil fuels, minerals, metals, clay and peat. It is measured in kilograms of Antimony (Sb) equivalents.

- Ozone Layer depletion (ODP): Changes to atmospheric ozone will modify the amount of harmful UV radiation penetrating the earth’s surface with potential adverse effects on human health and ecosystems. It is measured in terms of CFC equivalents.

- Photochemical Oxidation (POCP): It includes the complex reactions between NOx and VOCs in presence of sunlight resulting in formation of ozone in the troposphere. It is measured in terms of Ethylene equivalent.

- Eutrophication (EP): This is caused by the addition of nutrients largely line nitrogen and phosphorus to a soil or water system which leads to an increase in biomass, damaging other lifeforms. It is measured in terms of Phosphates (PO4-3) equivalents.

- Acidification (AP): It is the deposition of acids causing a decrease in the pH, a decrease in the mineral content of soil and increased concentrations of potentially toxic elements in the soil solution. The major acidifying pollutants are SO2, NOx, HCL and NH3. It is measured in terms of SO2

- Toxicity: It is the degree to which something is able to produce illness or damage to an exposed organism. There are 3 different types of toxicity; human toxicity (HTP), terrestrial ecotoxicity (TEP), and fresh water aquatic ecotoxicity (FAEP). It is measured in terms of dichlorobenzene equivalents.

LCA Findings of Alternative Polymer Packaging

PLA (Polylactic acid)

Bio-PET (Polyethylene Terephthalate)

Polybutylene succinate (PBS)

Polybutylene succinate (PBS) is a thermoplastic polyester. It can be produced from food waste. PBS has properties similar to polyethylene terephthalate (PET) and polypropylene (PP). The LCA analysis of PBS is based on GHG emissions, land acidification, and fine particulate matter production. GHG emissions from producing PBS from food waste are approximately 5.88 kg CO2-eq per kg of PBS (2)(3).

Bio-PE (Polyethylene)

Starch-based Biopolymer (SBP)

Cellulose acetate (CA)

LCA findings of NICHEM’s Biodegradable Additive

To know more, please visit our website www.nichem.solutions

About NICHEM

Long-standing Specialty Chemicals player with ISO 9001:2015 certification and a history of providing specialty solutions for over 25 years. The company is headed by senior chemical industry specialists with the combined expertise of more than 100 years. With an emphasis on eco-friendly, non-toxic products, the company’s primary strength is research, development, and customization. More information on NICHEM can be found at https://nichem.solutions.

References:

- Life Cycle Assessment (LCA) of BIOX Report (2022), National Institute of Industrial Engineering (NITIE), now known as IIM (Indian Institute of Management); pg 1-5.

- Sameh Samar Ali et al (2023), Bioplastic production in terms of life cycle assessment: A state-of-the-art review; Environmental Science and Ecotechnology; 15 (2023)100254; 1-21.

- Troy A Hottle et al (2013), Sustainability Assessments of Bio-based polymers; Polymer Degradation and Stability; 98 (2013) 1898-1907