Related Technical Articles

Materials and Methods

Materials:

The Bags used for this experiment were prepared in LDPE & NYLON. All were of same & were for every product testing, Control Bags of LDPE were used for comparison.

Table-1 gives details of the food products tested in Efficacy Testing.

Table-1: Food products tested in Efficacy Testing.

| No. | Product | Food Products |

| 1. | Freshness Plus Bags | Pomegranate |

| 2. | Lifeguard Bags | Mangoes |

| 3. | Halogen- CL Bags | Banana |

| 4. | Halogen-BR Bags | Banana |

| 5. | Halogen-IO Bags | Banana |

Methods:

- Quantitative Analysis –to check reduction in ethylene & carbon dioxide gas concentration in Bananas.

- Efficacy Testing – to study improvement in the shelf-life extension of fresh produce due to ethylene reduction.

- Quantitative Testing:

- Labeling of Test Samples (Table-2)

Table-2: Labelling of Test Products for Quantitative Analysis

No. Type of Product Labels 1. Control Control-LDPE 2. Control Control-NYLON 3. Freshness Plus Freshness Plus-LDPE 4. Freshness Plus Freshness Plus-NYLON 5. Food Fresh Food Fresh-LDPE 6. Food Fresh Food Fresh-NYLON 7. Anti-ripening CL Bags AR-CL-Micro AR-CL-Macro 8. Anti-ripening BR Bags AR-BR-Micro AR-BR-Macro 9. Anti-ripening IO Bags AR-IO-Micro AR-IO-Macro

- Labeling of Test Samples (Table-2)

Table-2: Labelling of Test Products for Quantitative Analysis

- Selection of Food Samples: Bananas were procured in semi-ripe form, no visual defects & with uniform maturity. Bananas were packed in perforated test films (0.5-0.7Kg per package) and stored at 20ºC.

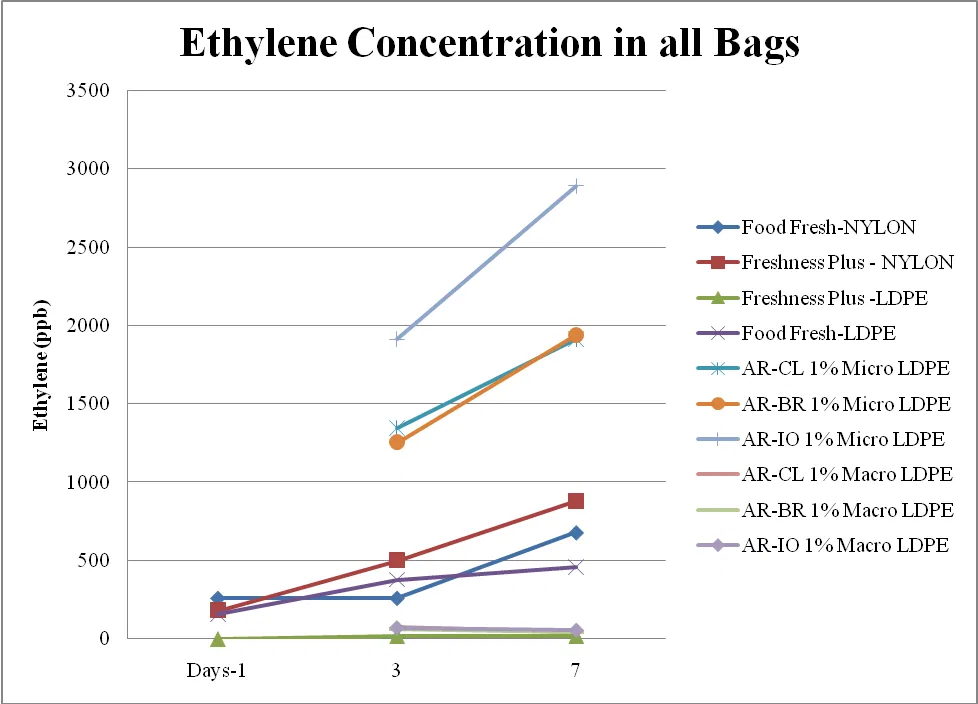

- Ethylene Concentration: The reduction in ethylene concentration was measured over a period of 7 days.

- Carbon Dioxide Concentration: % CO2 content was measured in each test bag over a period of 7 days.

- Efficacy Testing:

- Selection of Food Samples: Fruits and vegetables were procured in semi-ripe stage, with no visual defects and of uniform maturity.

- Placement of Bags: 500 gms of each of the respective food products were placed in the respective bags.

- Observation Parameters: All sets were observed till the Control Sets were non-marketable with respect to- i. Percent physiological loss in weight (% PLW), ii. Visual changes in the food products through photographs and iii. Sensory evaluation using Ranking Test.

Results and Discussion

- . Quantitative Testing

- Ethylene Concentration

Fig 1: Ethylene Concentration in all Bags

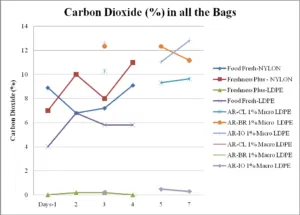

- Carbon Dioxide Concentration

- Physiological Loss in Weight (% PLW)

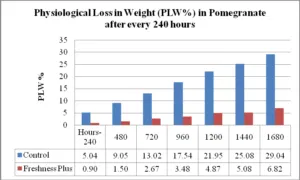

- Freshness Plus Bags:

Fig 2: Carbon Dioxide Concentrations in all bags

Of all the Bags (Fig-2), the % CO2 in Food Fresh LDPE was the lowest at the end of 7 days followed by Food Fresh NYLON Bags. % CO2 in Freshness Plus NYLON & Halogen Micro Bags was at par at the end of the test period.

Fig 3: Physiological Weight loss in Pomegranate

-

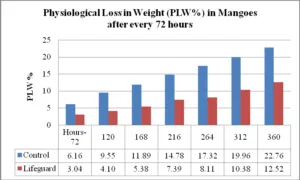

- Lifeguard Bags:

Fig 4: Physiological Weight Loss in Mangoes

(Temperature 20.2- 26.8 ºC and 37-56 % RH)

As seen in Fig-3, at the end of 65 days, Freshness Plus showed only 6.82 % PLW as compared to 29.04 for Control.

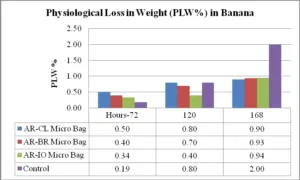

- Anti-Ripening Halogen Micro Bags – As seen in Fig-5, PLW (%) of Bananas increased during storage but was found to be the lowest (0.90 %) when packed in AR-CL Micro Bags as against Control Bags (2.00 %) at the end of the storage period of 7 days.Fig-5 Physiological Weight

- Visual Observation with Photographs

- Freshness Plus Bags:

Control–Day 70

Freshness Plus–Day 70

Fig 6: Pomegranate in Freshness Plus

b. Lifeguard Bags:

Lifeguard-Day 17 | Control –Day 17

Fig 7: Mangoes in Lifeguard

Conclusions

About NICHEM

Long-standing Specialty Chemicals player with ISO 9001:2015 certification and a history of providing specialty solutions for over 25 years. The company is headed by senior chemical industry specialists with the combined expertise of more than 100 years. With an emphasis on eco-friendly, non-toxic products, the company’s primary strength is research, development, and customization. More information on NICHEM can be found at https://nichem.solutions.

References:

- FAO, 2014 Website (fao.org).

- L. Raje, S. Sherlekar, K. Ramakrishnan, V.C.Malshe, G. Subbalakshmi, Post Harvest Preservation of mangoes by controlled release agents and adsorbent, Acta Horticulturae 455; 5th International Mango Symposium (1996).