Related Technical Articles

Sunscreen, also known as sunblock, sun lotion or sun cream, is a photoprotective topical product for the skin that helps protect against sunburn and prevent skin cancer. Sunscreens are available as lotions, sprays, gels, foam lotions, whipped lotion, sticks, powders and other topical forms. Sunscreens are classified according to the type of active ingredients present in the formulation. These actives are organic or inorganic compounds, also called as UV filters. There are hybrid Sunscreens available which contain a combination of organic and inorganic UV filters.

Understanding SPF

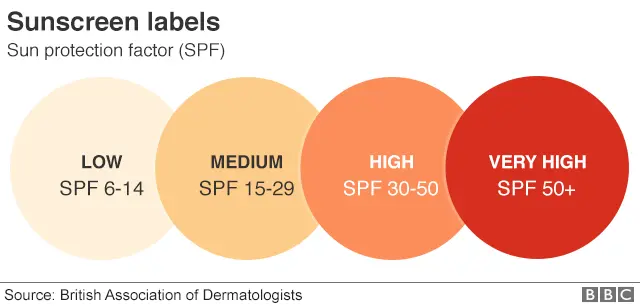

SPF is Sun Protection Factor. It is a measure of how much solar energy (UVB rays) is required to produce sunburn on protected skin (with Sunscreen) relative to unprotected skin (without Sunscreen). As the SPF value increases, sunburn protection increases. SPF is calculated as the ratio of UV exposure needed to cause minimal erythema (redness) on protected versus unprotected skin. Higher SPF values indicate greater protection, though no Sunscreen blocks 100% UVB. Broad-spectrum Sunscreens also shield against UVA, preventing deeper skin damage and photoaging. As depicted in Fig 1, the SPF number indicates how much UVB the Sunscreen allows in, not how much it blocks. A Sunscreen with SPF 15 allows one-fifteenth of the sun’s UVB rays to reach your skin, or about 7%. Thus, it filters out about 93% percent of UVB rays while SPF 30 filters about 97%.

Fig 1: SPF number on Sunscreen labels

Globally approved actives for SPF

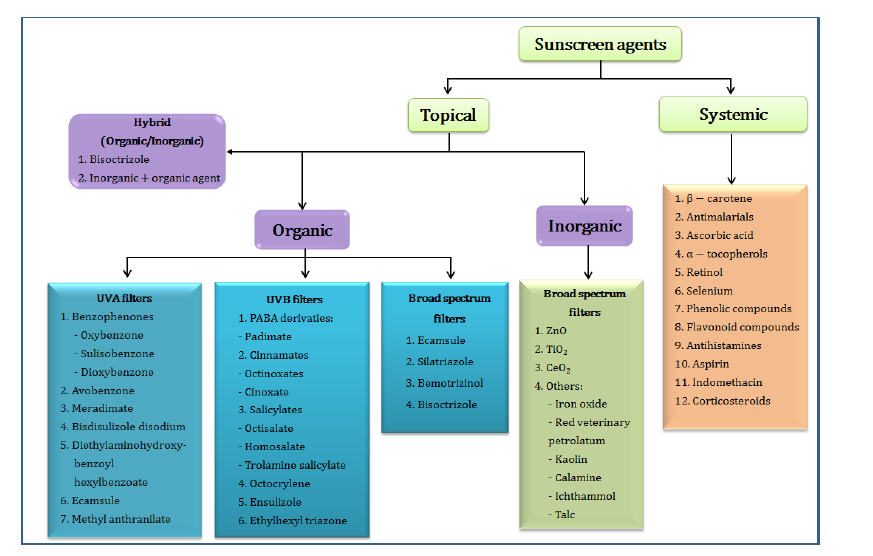

In the topical Sunscreen formulations, UV protection is imparted by 2 types of actives as depicted in Fig 2 –

- Mineral (Inorganic) Actives (also called as Mineral UV filters). These are inorganic compounds which reflect, scatter and absorb UV light. Zinc Oxide and Titanium Dioxide are the most widely used and approved UV filters in Sunscreen formulations.

- Chemical (Organic) Actives (also called as Chemical UV filters). These are organic compounds which absorb UV light. These actives are regulated in USA, EU, Japan and Australia. US-FDA have approved a limited number of Chemical UV filters, namely Octinoxate (Ethylhexyl Methoxycinnamate), Avobenzone (Butyl Methoxydibenzoylmethane), Octocrylene, Oxybenzone (Benzophenone-3), Homosalate, Octisalate (Ethylhexyl Salicylate). EU, Australia, Japan have approved a broader range of filters that offer enhanced photostability and broader spectral coverage. They are Mexoryl SX (Ecamsule), Mexoryl XL (Drometrizole Trisiloxane), Tinosorb S (Bis-Ethylhexyloxyphenol Methoxyphenyl Triazine), Tinosorb M (Methylene Bis-Benzotriazolyl Tetramethylbutylphenol), Uvinul A Plus (Diethylamino Hydroxybenzoyl Hexyl Benzoate), Uvinul T 150 (Ethylhexyl Triazone).

Fig 2: Types of Sunscreen Agents

Benefits of Mineral Sunscreens & Chemical Sunscreens

Mineral Sunscreens offer superior advantages over Chemical Sunscreens as depicted in Table 1 below:

Table 1: Comparative benefits of mineral & chemical sunscreens.

Criteria | Mineral (inorganic) Sunscreens | Chemical (organic) Sunscreens |

Mechanism of Action | Form a physical barrier that reflects and scatters UV rays | Absorb UV rays and convert them into heat |

Onset of Protection | Work immediately upon application | Often require 15–20 minutes to become fully effective |

Skin Sensitivity | Gentler on sensitive or acne-prone skin | May cause irritation in sensitive skin, though newer formulas improve |

Cosmetic Appeal | Can leave a white cast (improved with nano formulations) | More transparent with a lighter, non-greasy feel |

Photostability | Highly stable under sunlight, with minimal degradation | Some ingredients may degrade under UV exposure unless stabilized |

Environmental Impact | Often considered more reef-safe when formulated appropriately | Some filters (e.g., oxybenzone) have raised environmental concerns |

One potential drawback of mineral sunscreens is the white cast they can leave on the skin, especially in higher concentrations. However, advancements in formulation have led to the development of dispersions which are essential for the uniform distribution of the actives, improving stability, reducing whitening and improving overall performance of the Mineral Sunscreens.

Essential factors of an effective Sunscreen

A sunscreen formulation consists of following essential ingredients, namely –

- Active UV Filters:

- Chemical (Organic) filters to absorb UV rays and convert them into harmless heat. Examples include avobenzone, octinoxate, octocrylene, oxybenzone, homosalate, and octisalate.

- Physical (Mineral) Filters: to reflect and scatter UV rays. Common examples are zinc oxide and titanium dioxide.

- Emollients and Moisturizers: to spread the product evenly over the skin, enhance hydration, and improve the overall texture.

- Film-Forming Agents: to help the active ingredients adhere to the skin, maintaining consistent protection, especially during water exposure.

- Stabilizers and Antioxidants: to protect the formula from degradation (e.g., by UV light) and combat free radicals that can damage skin cells.

- Solvents, Emulsifiers, and Preservatives: to assist in blending oil- and water-based components and ensure the product remains stable and free from microbial contamination over time.Each of these components plays a vital role in creating a Sunscreen that is both effective and pleasant to use.

Each of these components plays a vital role in creating a Sunscreen that is both effective and pleasant to use.

Some critical factors determine the efficacy, aesthetics and safety of a sunscreen formulation. These include Particle Size of actives, Stability of formulation under various conditions, Medium of Dispersion, Agglomeration of formulation and Rheology of formulation

1. Particle size of active ingredients

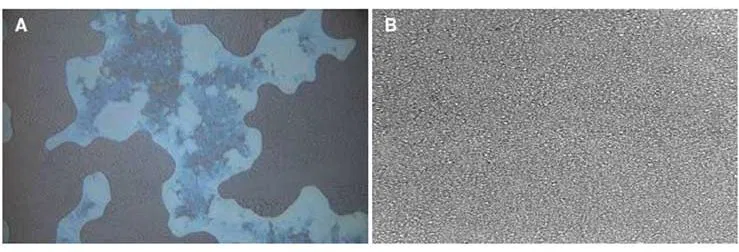

The particle size influences the transparency of the Sunscreen on the skin, its ability to provide even coverage, and the potential for skin whitening (white cast). Optical Microscopy helps to evaluate if the Sunscreen dispersion is satisfactory as seen in Fig 3. Image A represents a blotchy, non-uniform formula showing agglomeration of zinc oxide. Image B represents a uniform dispersion.

Nanoparticles are often used to reduce the white cast and improve the even distribution of the active ingredients on the skin, ensuring more uniform protection. However, there are concerns about potential skin penetration and safety. Thus, regulatory agencies may have specific guidelines regarding the use of nanoparticulate Sunscreen ingredients. As an alternate, micro-sized Zinc Oxide and Titanium Dioxide are used.

Fig 3: Optical microscopy of dispersion differences for zinc oxide in an emulsion. (A) Inadequate dispersion (B) Adequate dispersion.

2. Stability of formulation under various conditions

The stability of Sunscreen formulation is determined by various factors like temperature, light, pH, microbial presence, container compatibility, freeze-thaw conditions and accelerated aging.

- Temperature Stability: helps to assess the potential for phase separation, crystallization, or other changes in the formula after prolonged exposure

- Light Stability: helps to assess impact of UV exposure and other light conditions. Packaging may also play a role in protecting the formulation from light degradation.

- pH Stability: helps to assess the effectiveness and stability of mineral Sunscreen actives at different pH conditions.

- Microbiological Stability: helps to assess the absence of microbes in formula throughout the shelf life. This is important factor to achieve in-can preservation and prevent skin infections.

- Container Compatibility: helps to assess the interaction of the formula with different packaging materials that would affect the quality and stability.

- Freeze-Thaw Stability: helps to assess stability at freeze-thaw conditions, especially during transportation or storage.

- Accelerated Aging Studies: help to assess the long-term stability of the product within a shorter timeframe.

3. Medium of dispersion

The medium of dispersion used in Sunscreens is water, oil or silicone.

- Water-based Dispersion (Aqueous Phase): Sunscreen actives can be dispersed in water (aqueous phase) in water-in-oil (W/O) or oil-in-water (O/W) emulsions. They are lightweight, non-greasy, and suitable for daily use, hence preferred for facial Sunscreens.

- Oil-Based Dispersion (Oil Phase): Oil-based dispersions are often used in water-resistant Sunscreens, providing a more water-resistant film on the skin.

- Silicone based dispersion : Silicone-based carriers, such as dimethicone or cyclopentasiloxane, are often used as a medium of dispersion for mineral Sunscreen actives. They provide a smooth, non-greasy feel on the skin and can enhance the spreadability of the Sunscreen.

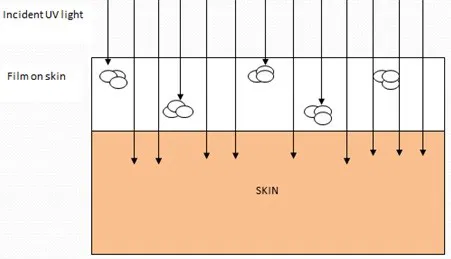

4. Agglomeration of formulation

Agglomeration is defined as a process of accumulating fine material into cohesive units such as pellets or granules. The granules are call agglomerates. These clusters of particles can affect the even distribution of active ingredients on the skin. Agglomeration can occur due to improper formulation techniques, leading to uneven protection as seen in Fig 4. Techniques such as high-pressure homogenization and proper choice of stabilizers can help prevent agglomeration.

Fig 4: Agglomeration of UV filters and low SPF protection

5. Rheology of formulation

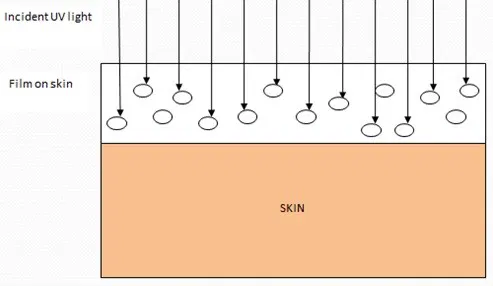

Rheology is the study of how matter flows and deforms. Sunscreen formulations with appropriate rheology spread evenly on the skin, ensuring uniform coverage as seen in Fig 5. The viscosity of the formulation affects its ability to adhere to the skin during application.

Fig 4: Homogenous distribution of UV filters will enable the best SPF results

New trends in Sunscreen formulations

- Reef-Safe and Eco-Friendly Formulations: The focus is more on natural and sustainable connotations instead of ingredients like oxybenzone and octinoxate

- Use of Bio-Adhesive Nanoparticles: UV filters based on sinapate esters are under study which remain non-adherent and non-penetrant to the skin.

- Advanced Formulation Technologies: Nano- and micro-encapsulation of UV filters enhance photostability and reduce the white cast often associated with mineral sunscreens.

- Broad-Spectrum and Multi-Functional Products: There is an increasing focus on broad-spectrum protection that covers UVA, UVB, and even visible light with antioxidants and anti-aging ingredients to offer additional skincare benefits.

- Tinted and Lightweight Options: Consumers prefer using sunscreens which provide a sheer tint to even out skin tone without the heavy or greasy feel.

- Regulatory and Ingredient Innovations: Newer, more effective UV filters are being approved in various regions.

NICHEM Sunscreen Actives belong to the non-nano, non-cast category offering effective SPF in the end formulations, keeping pace with environment friendly solutions. We have the expertise to control the particle size to an extent which will not be patchy on the skin and use different dispersing bases that would suit different end formulation matrices.

About NICHEM

Long-standing Specialty Chemicals player with ISO 9001:2015 certification and a history of providing specialty solutions for over 25 years. The company is headed by senior chemical industry specialists with the combined expertise of more than 100 years. With an emphasis on eco-friendly, non-toxic products, the company’s primary strength is research, development, and customization. More information on NICHEM can be found at https://nichem.solutions.

References:

- https://en.wikipedia.org/wiki/Sunscreen

- https://www.fda.gov/about-fda/center-drug-evaluation-and-research-cder/sun-protection-factor-spf

- https://en.wikipedia.org/wiki/Sunscreen

- https://www.bbc.com/news/health-43966154

- https://en.wikipedia.org/wiki/Sunscreen

- https://www.fda.gov/media/153965/download?attachment

- https://www.amixon.com/en/glossary/agglomeration-granulation#

- https://www.azom.com/article.aspx?ArticleID=21790

- https://dpderm.com/blogs/news/what-does-spf-50-pa-sunscreen-mean

- https://cosmetics.specialchem.com/tech-library/article/improving-performance-and-skin-feel-of-spf-products

- https://www.nativessentials.com/blogs/clean-beauty-notes/how-to-read-a-sunscreen-label-spf-pa-broad-spectrum-ratings

- https://www.happi.com/issues/2020-06-01/view_features/best-practices-for-formulating-sunscreen-with-zno/

- https://www.teamdrjoseph.com/en/c/journal/mineral-sunscreen/#:~:text=It%20is%20a%20white%2C%20fine,enough%20to%20penetrate%20the%20skin.

- https://www.frontiersin.org/articles/10.3389/fmats.2023.1273659#:~:text=TiO2%20exhibits%20an%20absorption,and%20Pavel%2C%202011%3B%20Reinosa%20et

- https://www.centerfordermatologyandlaserskinsurgery.com/skin-care/mineral-chemical-hybrid-sunscreens/

- https://www.researchgate.net/publication/336974753_Recent_Trends_of_Sunscreen_Cosmetic_An_Update_Review