Metals (ferrous & non-ferrous) are susceptible to environmental physical, chemical, or electrochemical deterioration when these come in contact with moisture and oxygen. Metals form an oxide layer on the surface which indirectly protects metal if oxide is denser than the parent metal. Only oxygen or only water cannot cause corrosion of the metals, both constituents must be present together to cause corrosion.

There are plenty of technologies available to protect metals from atmospheric corrosion such as barrier coatings like paint, plastic, and powder, peelable coatings, rust preventive oils, cathodic protection, dip galvanization, etc. restricting metal surfaces from acidic vapors, chloride, bromide corrosion. The major problems arise while the packaged part or equipment is unpacked. The paint, oil, or coating leaves a residue while cleaning [1].

Polyethylene film offers many advantages as a packing material. Polyethylene packaging in conjunction with Vapor Corrosion Inhibitors (VCI) is the most effective solution to metal jobs in the transportation industry. The impermeable morphology of the film makes packaged objects free from water vapor, oxygen in combination with most other contaminants in the atmosphere. However, the diffusion of VCI molecules into the headspace of the package became a concern when it encounter a high level of acid gas contaminations. The film is available in markets with different sizes ranging from 25-150 µm thickness and combination with metalized aluminum layers (multilayer films). Conventional polyethylene films are more permeable to water vapor, acid, and other gas constituents than the multilayer films. The diffusivity varies with thickness and the type of polymeric materials. In addition to ease of handling, it is also fully recyclable.

VCIs are organic compounds that include primary, secondary amines, and azole compounds. Cyclohexyl ammonium carbonate (CHAC), diisoporopylammonium nitrite (DIPAN) and dicyclohexyl ammonium nitrite (DICHAN)[2], Benzotriazoles [3], 6-methoxy-aminobenzothiazole derivatives[4], 1,6-diaminohexane [5] for Al, Zn, Mild Steel (MS). The parent compounds have specific vapor pressure under ambient conditions to essentially cover the surface of the metal by adsorption. In presence of moisture, the VCI active becomes polarized, and is attracted towards anode or cathode of the metal which protects the metal corrosion from the electrochemical process by adsorbing ions on the surface. Among these chemistries, primary amines are ecologically safe, non-toxic in nature, and are also admissible in REACH compliance.

Sample preparations: Mild steel (DN EN 10025) Samples were polished with 180-220 fine grit paper sized 7 cmx7.5 cm x0.2 cm. The sample was kept in ethanol at 60°C for 5 minutes to make the surface free from acid and moisture. This was followed by drying the samples at 80°C for 10 minutes to completely dry the surface for the testing.VCI additive preparation: The additive was prepared by mixing primary amines and some proprietary additives, was stirred at 600 rpm at room temperature. The 10% active based LLDPE masterbatch (MB) was extruded in Steer make twin-screw extruder (Alpha 18) with 44 L/D ratio at 130-160°C temperature. The LDPE (24FS 040 by Reliance industries) film was processed at 8-10% VCI MB concentration by blown film extruder to form a 100 µm thickness. The VCI film was tightly rolled and packed in an aluminum foil bag to avoid vaporization of VCI active from the film. After a conditioning period of 24 hours, the film was tested as per the standard efficacy testing.

The test was the primary indication of suitability of VCI molecule in contact corrosion-inhibiting ability conditions [6]. It was conducted by cleaning the MS blade with soap water solution and drying it with tissue paper. Then the blade was kept in a VCI film pouch. A few drops of water were added to the pouch and the pouch was sealed completely. The corrosion rate of the blade was observed for 2 hours.

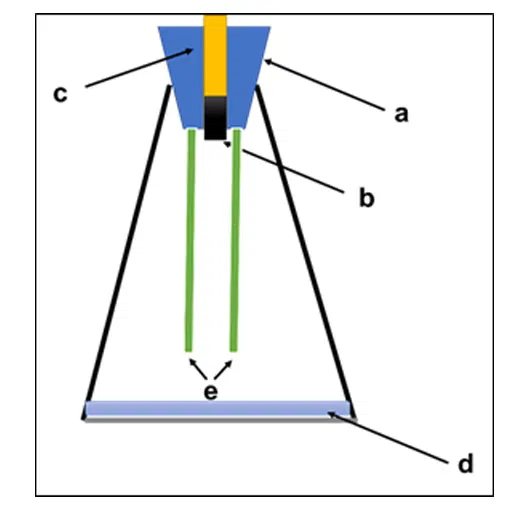

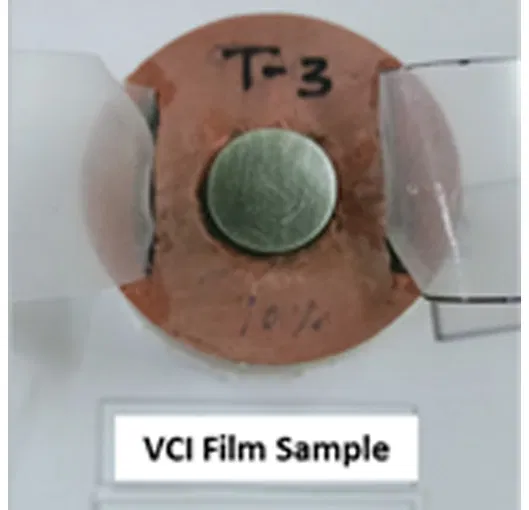

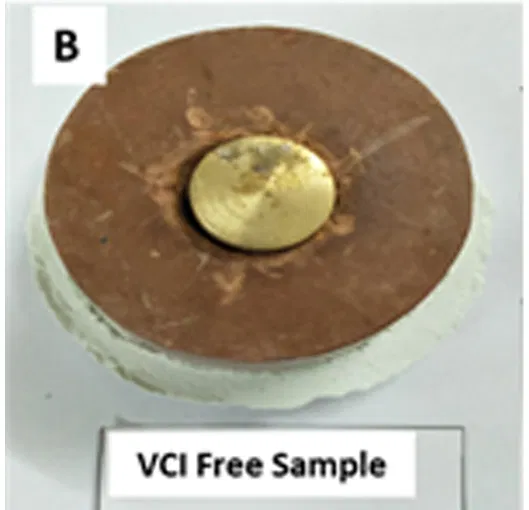

German VIA test was a quick method to evaluate the efficiency of VCI film in non-contact conditions. The test comprises an Erlenmeyer flask of 1 liter capacity in which the metal cylinder of 12mm x 16mm diameter in size was mounted at the center of rubber bung (Upper diameter 54 mm, lower diameter 45 mm with 15mm x 15 mm diameter hole) and film stripes of (25mm x150 mm) were suspended in the two slits 5 mm apart (fig.1). The corrosion media used was 1:2 Glycerin: water solution (1.076 gm/cc). The metal cylinder samples were polished with 220-320 grade fine grit paper followed by exposing them in boiling ethanol solvent for 5 minutes at 60°C and dried with dry cotton cloth/ tissue paper. Then VCI film samples, metal cylinders were fixed into the rubber bung slits such that there will be no contact of stripes and metal samples. The film must not touch glycerol solution. The rubber bung was fixed at the mouth of the flask and contours were sealed with white cement to prevent leakage of air/ VCI vapor. The samples were kept for 20 hours in equilibrium period (absence of Glycerin: water solution) to build up the VCI active substances on the metal surface. After completion of equilibrium period 10 ml glycerin: water mixture was introduced in the flask and sealed properly. After 2 hours of conditioning, the samples were exposed for 2 hours in the oven at 40±2°C [7]. The results were evaluated as per the German VIA test rating chart. The assembly is shown in fig.1.

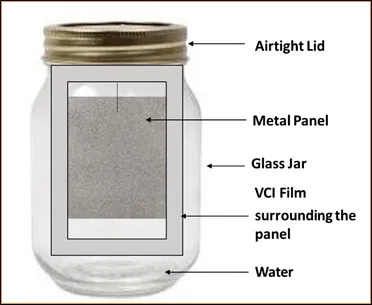

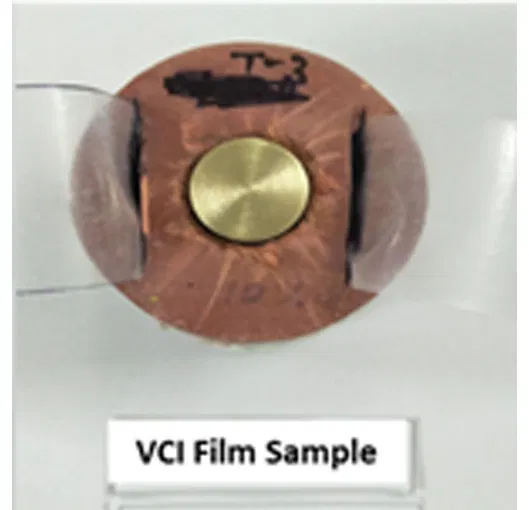

It was a long-duration test that consists of 240 hours in total cycles. The polished metal samples (7cm x 7cm x 2mm) were suspended in the center of a glass jar, which was surrounded with VCI film (28mm x 10 mm) cylinder at the mouth and closed with a lid (fig.3) for 20 hours equilibrium period (without corrosion media). After completion of equilibrium period, 30 ml of demineralized water was added to the jar, and closed the lid was closed with masking tape. The samples were exposed for 12 hours at 400C in the oven and 12 hours at 100C in a refrigerator. The samples were subjected to 10 such cycles. The test evaluation rated at corrosion observed on the metal surface in terms of percentage such as below 1% called as NO Corrosion and the rating increased from mild to heavy corrosion category.

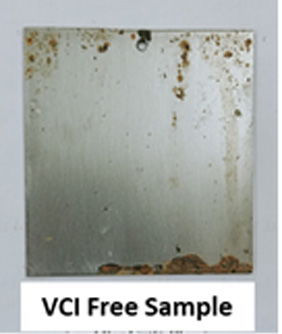

The test is known to evaluate the corrosion resistance of coating materials in a saline vapor environment. The metal plate samples (7cm x 7cm x 2mm) were sealed with VCI and VCI free film and suspended in a Salt spray chamber (400mm x 400mm x 300mm). 6 liters of 5% NaCl solution was added to the reservoir to form a salt fog atmosphere in the chamber, the temperature was set to 35±2 °C and air pressure was adjusted between 15-25 psi as per the standard. Fog collection device fixed into the chamber to measure the fog rate (1-2 ml/hour). The samples were exposed in the chamber for 100 to 500 hours. The test environments can be altered as per the requirement of the final applications [8].

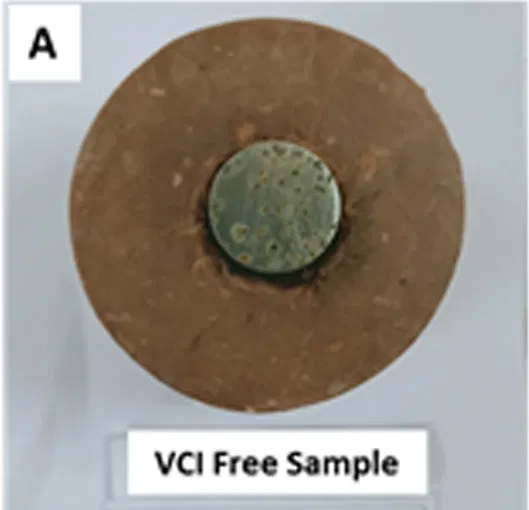

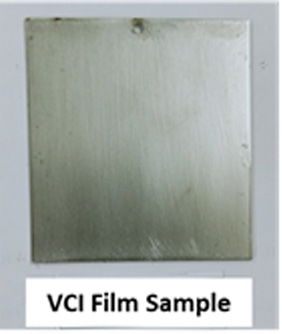

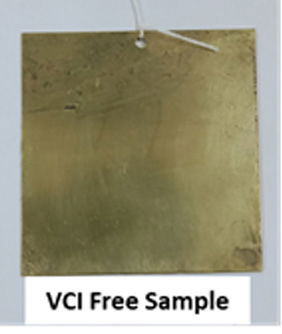

The VCI pouches showed no corrosion on MS blade & Brass panels, unlike the Control sample. Which was an indication of the effectiveness of VCI molecules under contact testing conditions(fig.4).

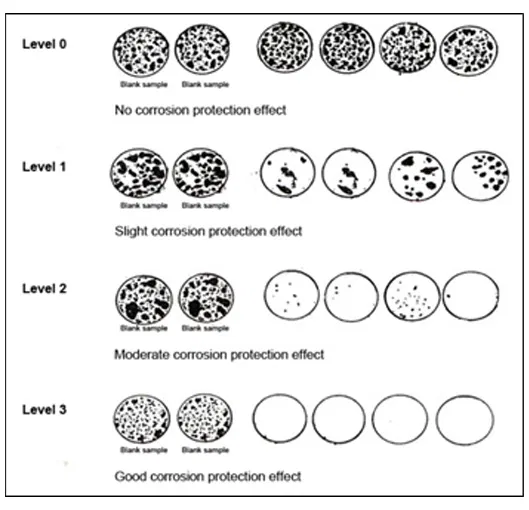

As per the standard the VCI film showed a G3 rating which depicts good corrosion protection to metals. The strong VCI molecule survived in the non-contact test environment. As per fig no. 5, the VCI free samples had corrosion spots with a G1-G0 rating.

The film successfully passed 240 hours cycles with different temperature conditions as per the standard (fig.6). The test depicts the long-term performance of the VCI molecules which enabled its adaptability in sustainable applications.

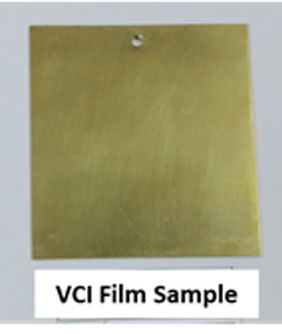

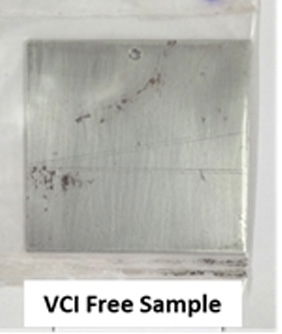

This test determined the activity of the VCI molecules under salty and severe corrosive conditions. VCI samples were tested for relative performance with control samples for 500 loading cycles. Where the Control sample was failed at 100 hours of salt spray exposure (Fig.7). On the other hand, VCI film had a spotless encapsulated surface up to 500 hours of exposure.

The above extensive study of green VCI film ensures its performance longevity which facilitates a wide range of applications in terms of corrosion protection.

Controlled release of Green VCI film ensures the acceptance in transportation, aviation, defense applications. Protection of Ferrous as well as non-ferrous materials affirms a wide range of scope of VCI film in metal packaging applications with the different corrosive environments. The non-toxic nature of the final product produces a safe environment for the use and handling of the products in processing operations. Transparent VCI films demonstrated corrosion inhibition for metals against high concentrations of external environments.

[1] Donald A. Kubik, New Technology for Vapor Corrosion Inhibiting (VCI) Transparent Plastic Packaging Combined with Acid-gas Scavenging (AGS), NACE international-corrosion conference and expo, 2010

[2] U. Kunzelmann, H.J. Jacobasch, G. Reinhard, Werkst. Korros. 40, 723, 1989.

[3] B.A. Miksic, M. Tarvin, G.R. Sparrow, NACE Corrosion 89, New Orleans, USA, April 4–8, paper 607, 1989, paper 607

[4] W. Skinner, Corros. Sci. 35,1491, 1993.

[5] M.A. Quraishi, D. Jamal, Corrosion 58, 387, 2002.

[6] Alla. Y. Furman, Performance and Testing of Vapor Phase Corrosion Inhibitors, Corrosion, paper 04418, 2004

[7] Nelson cheng, Ascertaining the Effectiveness of VCI Anti-Corrosion Properties of Vappro VCI Inhibicard Coated with Vappro MBL2200 Using German Test Method TL 8135-002, research gate,2016.

[8] Michel prenosil, Volatile corrosion inhibitor coatings, Supplement to Materials Performance, 2001.